Datapaq® Reflow Tracker Thermal Profiling System

Key Features

Measure and track process stability

- Collect repeatable data and create SPC analysis to predict maintenance needs in advance

- Ensure and prove that solder profile specifications are met

- Fine-tune the soldering process to maximize throughput

- Automate the selection of oven settings for faster changeover times

Monitor the temperatures for every soldering application – including wave, reflow, vapor phase, selective, and rework stations.

- Temperature range: -100°C to 1370°C (-385°F to 2498°F) (type K thermocouples)

- User-replaceable Nimh battery pack

- Exceptionally slim footprint - less than 60mm (2.5”) wide and low height - less than 12mm (0.5”)

- Sampling rate as low as 0.05 seconds

- 50000 readings per channel in 6 and 12-channel formats

- High accuracy +/- 0.5°C (0.9°F)

- Easy-to-use Start/Stop buttons

- Communication via ultra-fast USB

- Battery recharging from any USB power outlet

The Datapaq® Reflow Tracker® temperature profiling system is comprised of specifically designed thermocouples, data loggers, protective thermal barriers, and Insight software, to help you optimize process and product quality.

Datapaq DP5 Datalogger

The Datapaq DP5 is a rugged and reliable temperature data logger utilizing the latest electronic technology to ensure the optimal size/performance balance. It is housed in a machined-from-solid aluminum case to ensure the longest service life and lowest cost of ownership.

The Datapaq DP5 features include:

Thermal Barriers

Employing the same insulation technology as that used in an aircraft's 'black box', Datapaq thermal barriers are housed in a rugged stainless steel casing, designed to last for many years. Rugged, yet lightweight, these barriers withstand process temperatures run after run. Our most popular barrier weighs only 0.7 kg (1.6 lb) and can survive temperatures of 300 ºC (572 ºF) for over eight minutes.

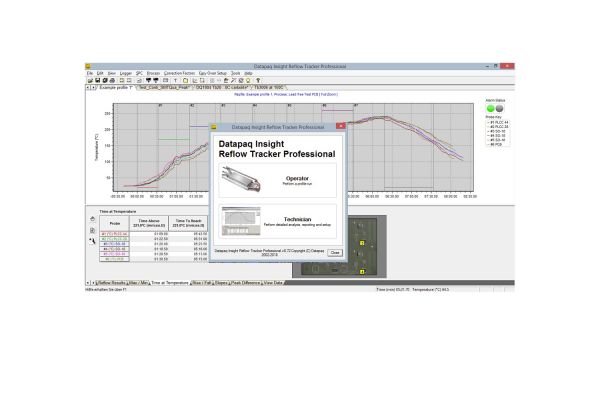

Insight Software for Reflow Tracker: Basic, Standard, and Professional versions

Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes in the following versions:

Insight Basic Software for Reflow Tracker has the power needed to convert raw data into information quickly and easily. It has wizards to guide infrequent users helping to ensure that each step is carried out efficiently. The result is a cost-effective and easy-to-use software solution that can used to analyze the soldering profile in depth and provide full reports on process performance.

Insight Standard Software for Reflow Tracker, the solution of choice for many users, builds on the basic software by adding both profile prediction and recipe calculation functionality. This transforms the basic profile analysis software into a full process optimization solution. The Easy Oven Setup recipe calculator can calculate the optimum oven settings in seconds, thus saving hours at every process changeover.

Insight Professional Software for Reflow Tracker is the choice of the frequent users and those in high-volume production environments. The Professional software includes the ability to eliminate the variability associated with the use of golden boards by use of the Datapaq Surveyor concept. The enhanced SPC Surveyor analysis software is designed to spot trends in your oven’s performance and avoid processes that are out of specification. Add the option of the adjustable width frame with Surveyor sensors, and you have the complete setup, optimization, and long-term process monitoring solution.

Thermocouples

Thermocouple probes are an essential part of a Datapaq Reflow Tracker system. They are placed at critical points on the product to give a clear profile of the temperature throughout the process. No one makes a more robust probe. All Datapaq probes are constructed with alloys that conform to the highest standards (ANSI MC 96.1 Special Limits of Error) and provide the most accurate data possible.

Datapaq DP5 Data Loggers

|

| Model Number | DP5660 | DP5661 | DP5662 | DP5612 | DP5622 |

|---|---|---|---|---|---|

| Dimensions | 11.7 x 106 x 150 mm 0.46 x 4.1 x 5.9” | 11.7 x 60 x 301 mm 0.46 x 2.3 x 11.8” | 20 x 57 x 165 mm 0.7 x 2.2 x 6.4” | 20 x 106 x 165 mm 0.7 x 4.1 x 6.4” | 20 x 60 x 237 mm 0.7 x 2.3 x 9.3” |

| Channels | 6 or 12 | ||||

| Temperature range | -100 to 1370°C (-148 to 2498°F) Dependent on thermocouple type (Type K shown) | ||||

| Connectivity | USB or Bluetooth* | ||||

| Memory capacity | 50,000 data points | ||||

| Start/stop triggers | Manual, Rising/falling temperature | ||||

| Sampling interval | 0.5 sec – 10 mins with no telemetry | ||||

| Accuracy | ± 0.5 °C (0.9 °F) – Type K | ||||

| Resolution | ± 0.1°C (0.18 °F) | ||||

| Thermocouple type | Type K (J,N,T,R, S,B are available) | ||||

| Multiple run capability | Up to 10 profile runs before returning to PC | ||||

*Contact Fluke Process Instruments for the availability of RF telemetry and Bluetooth in your country.

THERMAL BARRIERS SUITABLE FOR 6-CHANNEL DATA LOGGER – DP5660

| Model Number | TB2064 | TB2015 | TB2065 |

|---|---|---|---|

| Type | Low height thermal barrier* | Standard thermal barrier | Long-duration thermal barrier |

| Application | Ovens with very tight clearances | Standard processes and ovens | Longer and higher temperature processes |

| Dimensions | 20×133×210 mm (0.8×5.2×8.3”) | 25×133×210 mm (1.0×5.2×8.3”) | 29×133×210 mm (1.1×5.2×8.3”) |

| Weight | 0.6 kg (1.3 lb) | 0.68 kg (1.5 lb) | 0.68 kg (1.5 lb) |

| Thermal duration | 9 min @ 200ºC (392ºF) 8 min @ 250ºC (482ºF) 6 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 10 min @ 250ºC (482ºF) 9 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

* If rapid re-use is required or a longer than standard process is to be profiled, then consider TB2015 or TB2065.

THERMAL BARRIERS SUITABLE FOR 6-CHANNEL SUPER SLIM DATA LOGGER – DP5661

| Model Number | TB2066 | TB2067 | TB2068 |

|---|---|---|---|

| Type | Low height, super-slim thermal barrier | Standard, super-slim thermal barrier | Long-duration, super-slim thermal thermal barrier |

| Application | Low height, very narrow ovens | Standard height, narrow ovens, frequent profiling | Limited-size ovens, longer and higher temperature processes |

| Dimensions | 20×87×328 mm (0.8×3.4×12.9”) | 25×87×328 mm (1.0×3.4×12.9”) | 29×87×328 mm (1.1×3.4×12.9”) |

| Weight | 0.65 kg (1.4 lb) | 0.75 kg (1.7 lb) | 0.8 kg (1.8 lb) |

| Thermal duration | 8 min @ 200ºC (392ºF) 6 min @ 250ºC (482ºF) 6 min @ 280ºC (536ºF) | 11 min @ 200ºC (392ºF) 10 min @ 250ºC (482ºF) 8 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

THERMAL BARRIERS SUITABLE FOR 6-CHANNEL NARROW DATA LOGGER – DP5662

| Model Number | TB2020 | TB2021 |

|---|---|---|

| Type | Low height, narrow thermal barrier | Narrow thermal barrier with insulation for rapid re-use |

| Application | Ovens with limited width and height | |

| Dimensions | 28×84×223 mm (1.1×3.3×8.8”) | 35×84×223 mm (1.3×3.3×8.8”) |

| Weight | 0.5 kg (1.1 lb) | 0.65 kg (1.4 lb) |

| Thermal duration | 10 min @ 200ºC (392ºF) 8 min @ 250ºC (482ºF) 7 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

THERMAL BARRIERS SUITABLE FOR 12-CHANNEL DATA LOGGER – DP5612

| Model Number | TB2100 | TB2101 |

|---|---|---|

| Type | Low height, 12-channel thermal barrier | Standard 12-channel thermal barrier |

| Application | Low-height convection ovens or IR reflow soldering | Standard convection ovens or IR reflow soldering |

| Dimensions | 28×134×225 mm (1.1×5.3×8.9”) | 35×134×225 mm (1.3×5.3×8.9”) |

| Weight | 0.7 kg (1.5 lb) | 0.8 kg (1.8 lb) |

| Thermal duration | 10 min @ 200ºC (392ºF) 8 min @ 250ºC (482ºF) 7 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

THERMAL BARRIERS SUITABLE FOR 12-CHANNEL DATA LOGGER – DP5622

| Model Number | TB2081 | TB2082 |

|---|---|---|

| Type | Low-height 12-channel thermal barrier | Standard 12-channel thermal barrier |

| Application | Restricted-size convection ovens or IR reflow soldering | |

| Dimensions | 28×88×288 mm (1.1×3.4×11.3”) | 35×88×288 mm (1.3×3.4×11.3”) |

| Weight | 0.6 kg (1.3 lb) | 0.7 kg (1.4 lb) |

| Thermal duration | 10 min @ 200ºC (392ºF) 8 min @ 250ºC (482ºF) 7 min @ 280ºC (536ºF) | 13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

The Reflow Tracker system can be used to monitor the full range of circuit assembly manufacturing processes, reflow, and circuit board testing to ensure high-quality end products. Check our list of applications below or contact us with your specific application requirements.

- Wave soldering – with the CS5006 and CS5012 wave pallets, offering up to 9 contact sensors and 3 preheat sensors, the Reflow Tracker system offers a low-cost process monitoring solution for all wave soldering applications.

- Vacuum soldering – increasingly used to reduce voids in the joints. The small size and low thermal mass of the thermal barriers mean the Reflow Tracker system can be used in most vacuum soldering ovens.

- Vapor phase soldering - a range of sealed and lighter-weight thermal barriers enable users to profile this process with minimal process disturbance.

- Rework stations – the ability to monitor at high speed in real-time, either via the USB cable or Bluetooth connection, ensures the Datapaq DP5 is the ideal solution for monitoring rework stations of any type.

Manuals: (2)

- Reflow Tracker Manual

- Datapaq DP5 Data Logger Manual

Special and Custom Solutions The experienced engineering team at Fluke Process Instruments has produced numerous thermal barriers for applications, ranging from temperatures of -40°C to 1350°C (-40°F to 2462°F). They can design a complete solution for your specific requirements. Contact us to request information about a custom Datapaq thermal profiling solution. |

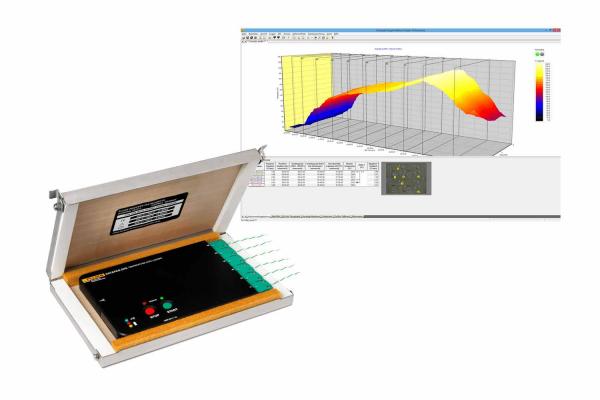

The Reflow Tracker Radio Telemetry System

The Reflow Tracker Radio Telemetry System allows you to see in real-time what happens to your product during the heat treatment process. You can compare actual product temperatures to specifications during the process and optimize cycle times. |

| Surveyor System consisting of an adjustable frame, fixed temperature sensors, and enhanced SPC Surveyor analysis software, available only in Insight Professional Software, this tool is designed to spot trends in your oven’s performance and avoid processes that are out of specification. |

| Wave Solder Analysis Kit is a tool for regular repeatable process monitoring. It enables you to profile PCB/component temperatures, or use the pallet with its integral PCB coupon to monitor process stability and wave conditions. All critical process parameters are displayed in one, easy-to-read table – the wave and preheat data, as well as the temperature profile graph. |

Thermocouples for use in the electronics assembly industry

PA0210 – Fast responsive exposed junction This is the standard thermocouple used throughout the reflow industry and is constructed from type K thermocouple wire. Each conductor is PTFE insulated and then twisted together to prevent tangling in use. The wire diameter is 0.2 mm (.007 in), providing a good compromise between size and strength. The thermocouple tip is pre-tinned to ease soldering to the PCB.

|

PA1683 – Fine wire This thermocouple has been developed specifically for use with BGA and ultra-fine pitch surface mount components. The type K thermocouple conductors are 0.1 mm (.003 in) in diameter, each insulated with PTFE. The two conductors are then over-wrapped with a single outer PTFE sheath to prevent tangling in use. The recommended attachment method is activated flux and high-temperature solder.

|

PA1571 – Ultra fine diameter, mineral insulated The PA1571 is intended for use in high-temperature applications. It is a Type K mineral insulated thermocouple with an Inconel outer sheath. The overall diameter is 0.5 mm (.01 in). The attachment method will depend on the application, but can include ceramic cement or mechanical fixtures.

|

PA0215 – Fiber-insulated probe Exposed junction type K thermocouple constructed from 0.2 mm (.007 in) wire with glass fiber insulation. This probe is designed for continuous use up to 355 ºC (671 ºF) and is therefore ideally suited to high-temperature soldering applications. For best results, we recommend that the probe is attached using an activated flux and high-temperature solder.

|

Probe Accessories

| PA0885 Surveyor sensor (horizontal plugs) long for use with DP5660 and Surveyor PA0883. Surveyor sensor using type K thermocouples to ANSI MC96.1 special limits of error. Dual horizontal thermocouple plugs are fitted to the mounting plate. |

| PA0886 Surveyor sensor (dual vertical plug) for use with DP5662 and DP5612 and Surveyor PA0884 Surveyor sensor using type K thermocouples to ANSI MC96.1 special limits of error. Fitted with a dual vertical plug. |

| PA1321 Wave solder contact sensor 420 mm long to be used on CS5006, CS5012 wave soldering pallets. |